This highlighted a real concern in the Australian building industry, with some authorities believing tens of thousands of home owners to be at risk from poor building materials.

Australia’s building design standards are some of the highest in the world and have been formulated with a safety first approach. However, current compliance monitoring of goods being brought into the country is not at acceptable levels, with industry sources suggesting that there is little more than an honour system currently in place. The result is that that many non-compliant goods are ending up on building hardware shelves and into people’s homes.

Low cost cladding is not the only example of low cost building materials putting Australians at risk. Shower screens and pool fences using sub-standard glass imported from China have literally exploded for no apparent reason, windows are found to be leaking after installation and miles of sub-standard electrical cabling has been placed in Australian buildings.

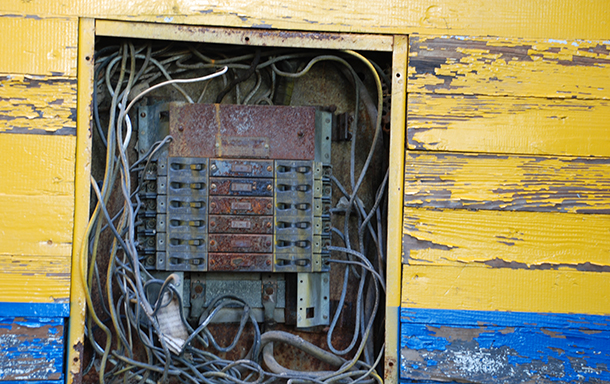

Sub-standard Electrical Cabling

One of the real concerns for experts in the building industry is the prevalence of substandard electrical cabling imported from China. The Australian Competition and Consumer Commission believes that over forty thousand homes are at serious risk of fire due to the installation of sub-standard electrical cabling.

The Infinity brand cabling has been found to be coated in sub-standard insulation. As a result it will degrade prematurely. While the ACCC says that there is no immediate danger, they expect that the cabling will start to degrade rapidly from 2016 onwards. After that time, the insulation will be liable to break if cables are disturbed. This could expose live wires and subject home owners to serious risk of electrical shock or fire.

According to the ACCC, the cables are likely to deteriorate at different rates depending upon such variables as temperature, and loads placed upon them. The cabling has been used in a variety of everyday situations, including power points, lighting, air-conditioning, ovens and hot water installations. Despite a national recall of the products, there is still an enormous amount of the cabling still unaccounted for.

The ACCC and other bodies are urging any home owners and businesses that have had electrical work done since 2010 to get their wiring checked by a suitably qualified electrical contractor. They stress that homeowners should not seek to inspect wiring themselves.

Faulty electrical cabling is an extremely dangerous example of what can happen when sub-standard foreign building materials are allowed into the market.

Consumers are being urged to ensure that builders and tradesman can demonstrate that materials being used in any project do comply with current Australian Design Standards. Perhaps, more importantly, any consumer who has purchased a new property, had renovations done, installed new appliances or had electrical work of any description done in the home or office recently should contact a licensed electrician as a matter of urgency to organise a safety inspection to determine if Infinity cables were installed.

As at the end of August just over 1% of the total cabling recalled has been successfully re-mediated. Do not delay – take the necessary steps to ensure that your home and office have safe electrical cabling installed.

The Everest Electrical team is, for a limited time, offering free electrical safety inspections for homeowners on Sydney’s North Shore and Northern Beaches. To arrange yours we welcome your call on 0410 229 139.